The Difference Between Electrolytic Polishing and Electropolishing for Stainless Steel Passivation

In the realm of surface refinement, two powerful techniques—electrolytic polishing and electropolishing—take the spotlight. Today, let’s unravel the intricacies of these processes, understand their differences, and explore why electropolishing stands out as the superior method for achieving stainless steel passivation.

What is Electrolytic Polishing?

Electrolytic polishing, often referred to as electrochemical polishing, is a method that utilizes an electrolyte bath and an electrical current to selectively remove material from the surface of a metal object. This controlled electrochemical process results in a polished and refined surface, enhancing aesthetics and providing some corrosion resistance.

How is it Different from Electropolishing?

While electrolytic polishing and electropolishing share similarities, the key difference lies in the mechanism of material removal. In electrolytic polishing, metal ions are selectively dissolved from the surface. On the other hand, electropolishing involves the dissolution of a thin, uniform layer of the metal surface. This distinction affects the level of precision, consistency, and overall effectiveness in achieving stainless steel passivation.

Why Electropolishing for Superior Stainless Steel Passivation?

1. Enhanced Precision and Consistency:

Electropolishing offers a more controlled and uniform removal of material. The process targets microscopic irregularities on the surface, resulting in enhanced precision and a consistent finish across the entire metal object. This precision is crucial for achieving the desired level of passivation.

2. Superior Surface Finish:

The dissolution of a thin layer of metal during electropolishing leads to an unparalleled surface finish. The resulting surface is not only smoother but also free from microscopic imperfections, contributing to improved corrosion resistance and longevity.

3. Comprehensive Passivation:

Electropolishing doesn’t just enhance the appearance of stainless steel; it goes beyond by contributing to the passivation of the material. By removing free iron and contaminants from the surface, electropolishing promotes the formation of a passive oxide layer, significantly improving corrosion resistance and ensuring a more durable and long-lasting stainless steel component.

Enhance your Stainless Steel with Electropolishing

As pioneers in surface treatment, we at New England Electropolishing advocate for the transformative power of electropolishing in achieving superior stainless steel passivation. If you’re in industries like aerospace, medical devices, or anywhere corrosion resistance is paramount, electropolishing is the key to unlocking surfaces that shine with precision and longevity.

Ready to explore the benefits of electropolishing for your stainless steel components? Contact New England Electropolishing today and witness the superior results that set us apart in the world of surface treatment.

Does Electropolishing Prevent Corrosion?

"Electropolishing is an electrochemical process that enhances metal alloys resistance to corrosion. Electropolishing is used to clean, deburr and passivate metals by removing impurities from the surface left behind from manufacturing processes."

Electropolishing Resources

What is Electropolishing?

Electropolishing is an electrochemical and reverse plating process that removes the outer layer of skin on a metal...

The Electropolishing Process

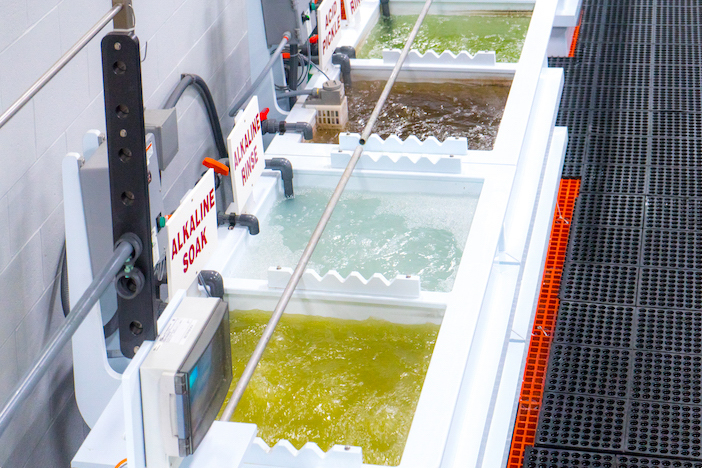

The electropolishing process is initiated by immersing a metal part into a temperature-controlled bath of electrolyte...

Benefits of Electropolishing

Curious about the benefits of putting your parts through the electropolishing process? Read along below where we...

How Much Material Does Electropolishing Remove?

Electropolishing, when done properly is a highly controllable process which removes as little as...

How Much Will Electropolishing Improve the Surface Finish of My Part?

Ra and RMS are both representations of surface roughness. Ra is calculated as the roughness average of a surface’s...

Electropolishing Frequently Asked Questions

Learn the difference between electropolishing and electroplating as well as how the electropolishing process works...

What is ASTM B912?

ASTM B912 is an industry standard for the passivation of stainless steel alloys through electropolishing...

What is ASTM A967?

ASTM A967 is an industry standard specification for the chemical passivation treatments for stainless...

What is ISO 13485?

ISO 13485 is a standard that applies specifically to medical devices. ISO 13485 is designed to be...