nitric and citric passivation

Passivation is the removal of contaminants from the surface grain boundaries of metals such as stainless steel to allow the growth of a natural, inert, oxide layer on the metal.

Customers rely on NEE for precise and consistent finish, from one part to 100,000.

nitric and citric Passivation

Understanding Chemical Passivation

Passivation is the removal of contaminants from the surface grain boundaries of metals such as stainless steel to allow the growth of a natural, inert, oxide layer on the metal. Contaminants such as sulfides (used in manufacturing processes) and free iron inhibit the formation of the oxide layer that protects metals like stainless steel from corrosion. In chemical passivation, such as nitric passivation or citric passivation, acid immersion is used to remove contaminants. When contaminants such as free iron are removed from the metal’s surface, they can no longer react with the atmosphere to form rust.

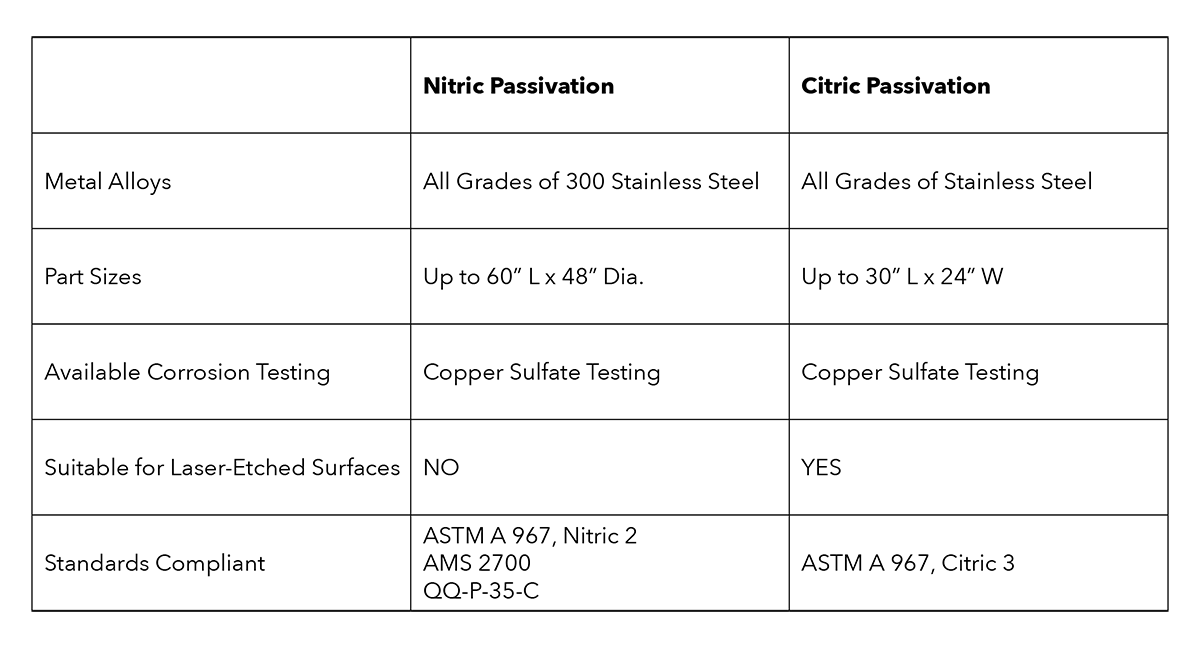

NEE Chemical Passivation Capabilities

To thoroughly address your needs, NEE also offers passivation through electropolishing services for the full range of stainless steel alloys.

We Are Here to Help

Tell us about your nitric passivation, citric passivation and application requirements. Our knowledgeable staff is ready to meet your needs with the electropolishing and passivation processes best suited to your parts and application. Contact us today.

Learn more about Passivation Through Electropolishing.

"Electropolishing is a science and an art. By combining both, we meet your exact finishing requirements, whether you need one part of 100,000. Our customers tell us no one does stainless steel electropolishing better."

Imad JaberOperations Manager