Electropolishing Blog

New England ElectropolishingCorrosion-Resistant Stainless Steel Treatments

Stainless steel is known for its natural corrosion resistance—but in many...

Protecting Chemical Processing Equipment with Citric Acid Passivation

Why Surface Treatment Is Essential for Corrosion Resistance in Harsh...

Using Citric Acid Passivation for Marine and Subsea Components

Stainless steel is widely used in marine and subsea applications for its...

Why Machined Stainless Steel Needs Passivation

Stainless steel is valued for its natural corrosion resistance—but...

Stainless Steel Treatment After Welding: Methods, Comparisons, and Best Practices

Welding is a critical step in the fabrication of stainless steel...

Acid Pickling for Stainless Steel

When it comes to finishing stainless steel components for...

How Long Does Passivation Last? Factors That Affect Its Durability

Stainless steel is known for its corrosion resistance, but without proper...

Electropolishing vs. Passivation: Understanding the Differences

When it comes to enhancing the corrosion resistance, cleanliness, and...

Our latest feature in Products Finishing highlights how bulk electropolishing enhances corrosion resistance, biocompatibility, and performance for surgical jaws

Precision and efficiency are critical in medical device manufacturing,...

Passivation in High-Humidity Environments: Protecting Stainless Steel Against Corrosion

High-humidity environments present unique challenges for stainless steel...

The Role of Passivation in Ensuring FDA Compliance for Food and Beverage Equipment

When it comes to the food and beverage industry, safety and compliance...

How to Verify the Effectiveness of Stainless Steel Passivation

Stainless steel passivation is a crucial process that enhances corrosion...

How to Passivate Stainless Steel Welds

Stainless steel is known for its corrosion resistance and strength, which...

Citric Acid Passivation: Enhancing Stainless Steel Longevity and Performance in Coastal and Marine Environments

Stainless steel’s durability and corrosion resistance make it an...

How Durable is an Electropolished Surface?

When it comes to selecting materials for applications in demanding...

Understanding ASTM A380: Cleaning, Descaling, and Passivation of Stainless Steel

ASTM A380 is the standard practice for cleaning, descaling, and passivating stainless steel parts, equipment, and systems.

Quality Standards in Electropolishing for Medical Devices

In medical device manufacturing, electropolishing ensures that stainless...

Advancing Medical Device Finishing with Sustainable Surface Treatments

In the medical device industry, precision, safety, and reliability are...

Understanding the Three Main Types of Stainless Steel: Austenitic, Ferritic, and Martensitic

Stainless steel is a versatile and durable material known for its...

Case Study: Restoring Corrosion Resistance for Stainless Steel Threaded Bolts

Client Background A leading manufacturer of precision-engineered parts...

Exploring the Eco-Friendly Benefits of Citric Acid Passivation

In the intricate landscape of medical device manufacturing, compliance...

NEE featured in Finishing and Coating Magazine

Recently Finishing and Coating published a feature on New England...

Ensuring Biocompatibility: Electropolishing and Orthopedic Devices

In the field of orthopedic medical device manufacturing, biocompatibility...

NEE Featured in article about Electropolishing on Finish and Coating

Recently Finish and Coating published and artcile on "Electropolishing...

MPO on Supplying Sustainable Surfaces for Medical Device Coating and Finishing

Recently Medical Product Outsourcing (MPO) interviewed several leading...

Understanding the importance of regulatory requirements in the passivation of medical devices and parts

In the intricate landscape of medical device manufacturing, compliance...

Introducing the NEE Inspection Manager Tool

The NEE Inspection Manager is an Excel-based tool with VBA automation...

Advancing Healthcare: The Crucial Role of Stainless Steel Medical Device Passivation

In the realm of healthcare, precision and reliability are paramount....

Enhancing Maritime Excellence: The Crucial Role of Stainless Steel Passivation in the Marine Industry

The marine industry stands as a testament to human ingenuity and...

Electropolishing for the Aerospace Industry

Elevating Aerospace Precision with Electropolishing Precision is the...

Does electropolishing prevent corrosion?

Does Electropolishing prevent corrosion? Yes. Electropolishing is an...

MPO on the Changes in the Medtech Surface Treatment Industry

Recently Medical Product Outsourcing (MPO) interviewed about a dozen...

Electropolishing Examples

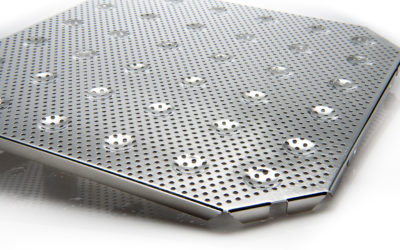

Electropolishing ExamplesElectropolishing can be used to improve and...

Laser Rust Removal

Laser technology, including laser rust removal, is a popular method for...

The Benefits of Electropolishing stainless steel for the Orthopedic Industry

Stainless steel electropolishing is a critical finishing process for the...

A Lasting Legacy – NEE Featured in the South Coast Almanac

Made on the South Coast More than a dozen multi-generational businesses...

Stainless Steel Electropolishing for the Semiconductor Industry

New England Electropolishing delivers precision stainless steel...

Passivation for Stainless Steel in the Chemical Processing Industry: Battling Corrosive Environments

The chemical processing industry operates in one of the harshest...

The Five Most Common Industries that Rely on Passivation for Stainless Steel Components

Passivation is a crucial finishing process that enhances the corrosion...

What is ASTM B912?

What is ASTM B912? ASTM B912 is an industry standard for the passivation...

Investing in Workforce Development to Increase Capacity

Amidst the national discussion around labor shortages, New England...

What is ASTM A967?

What is ASTM A967? ASTM A967 is an industry standard specification for...

Citric Acid Passivation

Citric Acid Passivation A Safer, Environmentally Friendly Way to Enhance...

How Much Material Does Electropolishing Remove?

How much material does electropolishing remove? Electropolishing can...

New England Electropolishing Celebrates it’s Best Month Ever, with an Employee Appreciation Event

There is something special about working at New England Electropolishing. Our business is family owned, and we treat our employees as an extension of the family.

Electropolishing Stainless Steel

Electropolishing Stainless Steel is an electrochemical process often referred to as “reversed plating”.

Understanding ISO 13485

Understanding ISO 13485 Understanding ISO 13485 ISO, or the international standards organization…

Introducing New England Electropolishing’s ‘Customer Support Squad’

Introducing New England Electropolishing’s ‘Customer Support…

Meeting Strict Deadlines in the Manufacturing Process

Our felixible and committted staff will do everything they can so our customers…

What is RA and RMS

What is RA and RMS? RMS and RA are two of the most widely used tools for...

Understanding Grade 440 Stainless Steel

Grade 440 stainless steel comes in multiple variations (440A, 440B, and...

Understanding 420 Grade Stainless Steel

Grade 420 stainless steel is another martensitic stainless alloy, known...

Understanding 410 Grade Stainless Steel

Grade 410 stainless steel is a martensitic alloy known for its high...

Understanding 17-4 Grade Stainless Steel

17-4 grade stainless steel, also known as Type 630, is a...

Understanding 303 Grade Stainless Steel

303 grade stainless steel is a highly machinable austenitic stainless...

Understanding 321 Grade Stainless Steel

321 grade stainless steel is an austenitic stainless steel that is...

Understanding 317 Grade Stainless Steel

317 grade stainless steel is a highly corrosion-resistant austenitic...

Understanding 316 Grade Stainless Steel

316 grade stainless steel is renowned for its enhanced corrosion...

Understanding 304 Grade Stainless Steel

304 grade stainless steel is one of the most widely used and versatile...

Electropolishing delivers precision finishing and passivation for medical and scientific lab equipment

Enhancing stainless steels corrosion resistance is critical for the sterilization…

ElectroMatte™ Provides All the benefits of Electropolishing, without the reflectivity

ElectroMatte™ Provides All the benefits of Electropolishing, without the

NEE Celebrates 35 Years of Excellence

NEE Celebrates 35 Years of ExcellenceThank you to our clients and employees for 35 amazing years

Laser Slag Removal for Medical Parts

Laser slag associated with drilled and cut holes is an unwanted effect of the laser cutting process.

Electropolishing Case Study: Battery Wharf – Boston, MA

Electropolishing can solve complex corrosion issues. Passivation restores

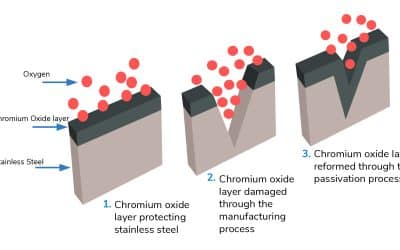

Passivation of Stainless Steel

The Passivation of Stainless Steel for Corrosion Resistance The...

Electropolishing meets strict standards of the medical industry

Electropolishing meets strict standards of the medical sector Surgical tools, implants,

Promoting stainless steel’s natural corrosion resistance through passivation

Promoting stainless steel’s natural corrosion resistance through passivation.

Electropolisher

Under moderate supervision, this position will electropolish and passivate formed metal products.

Why Process Validations Matter in Electropolishing

Why Process Validations Matter in Electropolishing Meeting Performance…

Family-Owned Electropolisher Delivers Metal Finishing with a Legacy

Family-Owned Electropolisher Delivers Metal Finishing with a Legacy. We may…

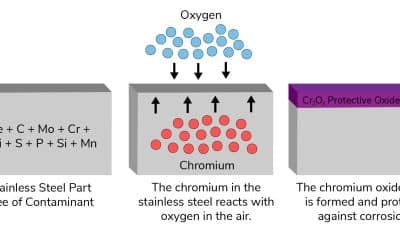

Why does stainless steel rust?

Why does stainless steel rust?The science behind stainless steel...

Stainless Steel Electropolisher

Stainless Steel ElectropolisherNew England Electropolishing – a stainless...

How Much Will Electropolishing Improve the Surface of my Part?

How Much Will Electropolishing Improve the Surface Finish of My Part?

What’s the Difference Between Electropolishing and Passivation?

What’s the Difference Between Electropolishing and Passivation?

Citric Acid Passivation for Underwater Load Cells and Torque Sensors

In demanding environments where corrosion resistance is critical, the...

Quality You Can Trust: How U.S. Load Cell Manufacturers Maintain the Highest Standards

When it comes to precision measurement, there’s no room for error. Load...

The Difference Between Electrolytic Polishing and Electropolishing for Stainless Steel Passivation

In the realm of surface refinement, two powerful techniques—electrolytic...

Unlocking Excellence: The Top Three Benefits of Citric Acid Passivation for Stainless Steel

Welcome to the world of precision surface treatment! At New England...

What is ISO 9001?

A Guiding Standard in Stainless Steel Electropolishing In the world of...

What is passivation?

Passivation is a critical surface treatment used to enhance the corrosion...

The Difference between Mechanical Polishing and Electropolishing

In the realm of metal finishing processes, two prominent methods stand...