Passivation for the Food and Beverage Industry: Ensuring Hygienic and Corrosion-Resistant Surfaces

The food and beverage industry operates under stringent regulations to ensure safety, hygiene, and product quality. In such environments, stainless steel equipment and surfaces must not only meet these standards but also withstand daily exposure to moisture, cleaning agents, and corrosive substances.

Stainless steel passivation is an essential process for maintaining the hygienic and corrosion-resistant properties of stainless steel components. By enhancing the natural protective layer on stainless steel, passivation ensures that food processing equipment remains safe, compliant, and durable over time.

Why Is Passivation Critical in the Food and Beverage Industry?

1. Preventing Corrosion

In food processing facilities, equipment is often exposed to acidic ingredients, cleaning chemicals, and high levels of humidity. Over time, these elements can cause corrosion, compromising the structural integrity of stainless steel.

Stainless steel passivation removes free iron and other contaminants from the surface, creating a passive chromium oxide layer that resists corrosion. This protective barrier extends the lifespan of equipment, reduces maintenance costs, and minimizes the risk of contamination from rust or degraded materials.

2. Maintaining Hygiene Standards

Hygiene is paramount in the food and beverage industry. Stainless steel is prized for its smooth, non-porous surface, which makes it easy to clean and sanitize. However, microscopic imperfections or contaminants can harbor bacteria and other pathogens, posing a risk to food safety.

The passivation of stainless steel ensures a uniform and defect-free surface, reducing the likelihood of microbial growth. This process supports compliance with food safety regulations, including those set by the FDA, USDA, and other governing bodies.

How Passivation Enhances Safety and Compliance

1. Resistance to Chemical Cleaners

Food-grade stainless steel must endure routine cleaning with strong chemicals to maintain sanitary conditions. Passivated surfaces are better equipped to handle these cleaning cycles without degrading, ensuring consistent performance.

2. Eliminating Surface Contaminants

During manufacturing, contaminants such as iron particles or debris can adhere to stainless steel. Without proper treatment, these contaminants can compromise the surface and lead to localized corrosion. Passivation effectively removes these impurities, leaving behind a surface optimized for food-grade use.

3. Adherence to Regulatory Standards

Many food safety standards require equipment to meet strict corrosion resistance and cleanliness benchmarks. The passivation of stainless steel ensures that components satisfy these requirements, giving manufacturers peace of mind and reducing the risk of non-compliance penalties.

Applications of Passivated Stainless Steel in Food Processing

- Mixing Tanks and Vessels: Ensures a clean, non-reactive surface for blending ingredients.

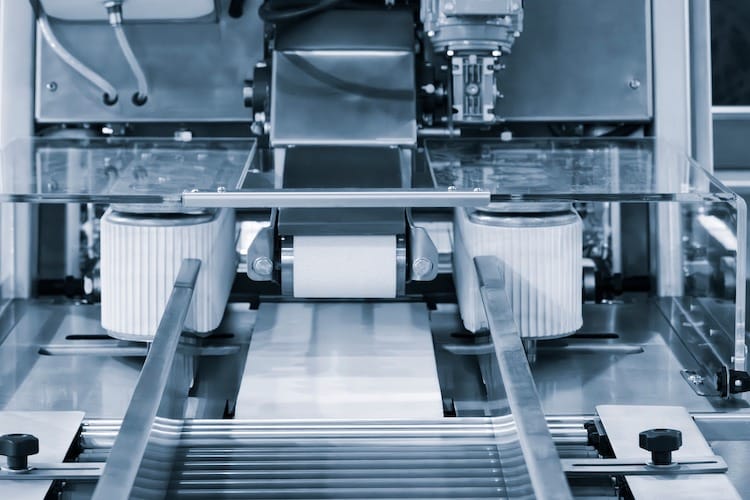

- Conveyor Systems: Enhances durability and corrosion resistance in high-moisture environments.

- Cutting Tools and Blades: Prevents rust and contamination during food preparation.

- Storage Containers: Maintains integrity in acidic or salty food storage conditions.

- Dairy and Brewery Equipment: Provides a hygienic, long-lasting surface for handling milk, beer, and other sensitive products.

Choosing the Right Passivation Partner

Proper passivation requires expertise, precision, and a commitment to quality. At New England Electropolishing, we specialize in stainless steel passivation for the food and beverage industry. Our processes ensure that your equipment meets the highest standards of hygiene, corrosion resistance, and regulatory compliance.

Conclusion

Passivation plays a critical role in the food and beverage industry by protecting stainless steel surfaces from corrosion and contamination. This process not only extends the lifespan of equipment but also ensures compliance with stringent hygiene and safety standards.

For more information about stainless steel passivation and how it can benefit your food processing operations, contact New England Electropolishing today. Let us help you maintain safe, durable, and reliable equipment for your facility.

Electropolishing Resources

What is Electropolishing?

Electropolishing is an electrochemical and reverse plating process that removes the outer layer of skin on a metal...

The Electropolishing Process

The electropolishing process is initiated by immersing a metal part into a temperature-controlled bath of electrolyte...

Benefits of Electropolishing

Curious about the benefits of putting your parts through the electropolishing process? Read along below where we...

How Much Material Does Electropolishing Remove?

Electropolishing, when done properly is a highly controllable process which removes as little as...

How Much Will Electropolishing Improve the Surface Finish of My Part?

Ra and RMS are both representations of surface roughness. Ra is calculated as the roughness average of a surface’s...

Electropolishing Frequently Asked Questions

Learn the difference between electropolishing and electroplating as well as how the electropolishing process works...

What is ASTM B912?

ASTM B912 is an industry standard for the passivation of stainless steel alloys through electropolishing...

What is ASTM A967?

ASTM A967 is an industry standard specification for the chemical passivation treatments for stainless...

What is ISO 13485?

ISO 13485 is a standard that applies specifically to medical devices. ISO 13485 is designed to be...