From Surgical Tools to Implants: Electropolishing Applications in the Medical Industry

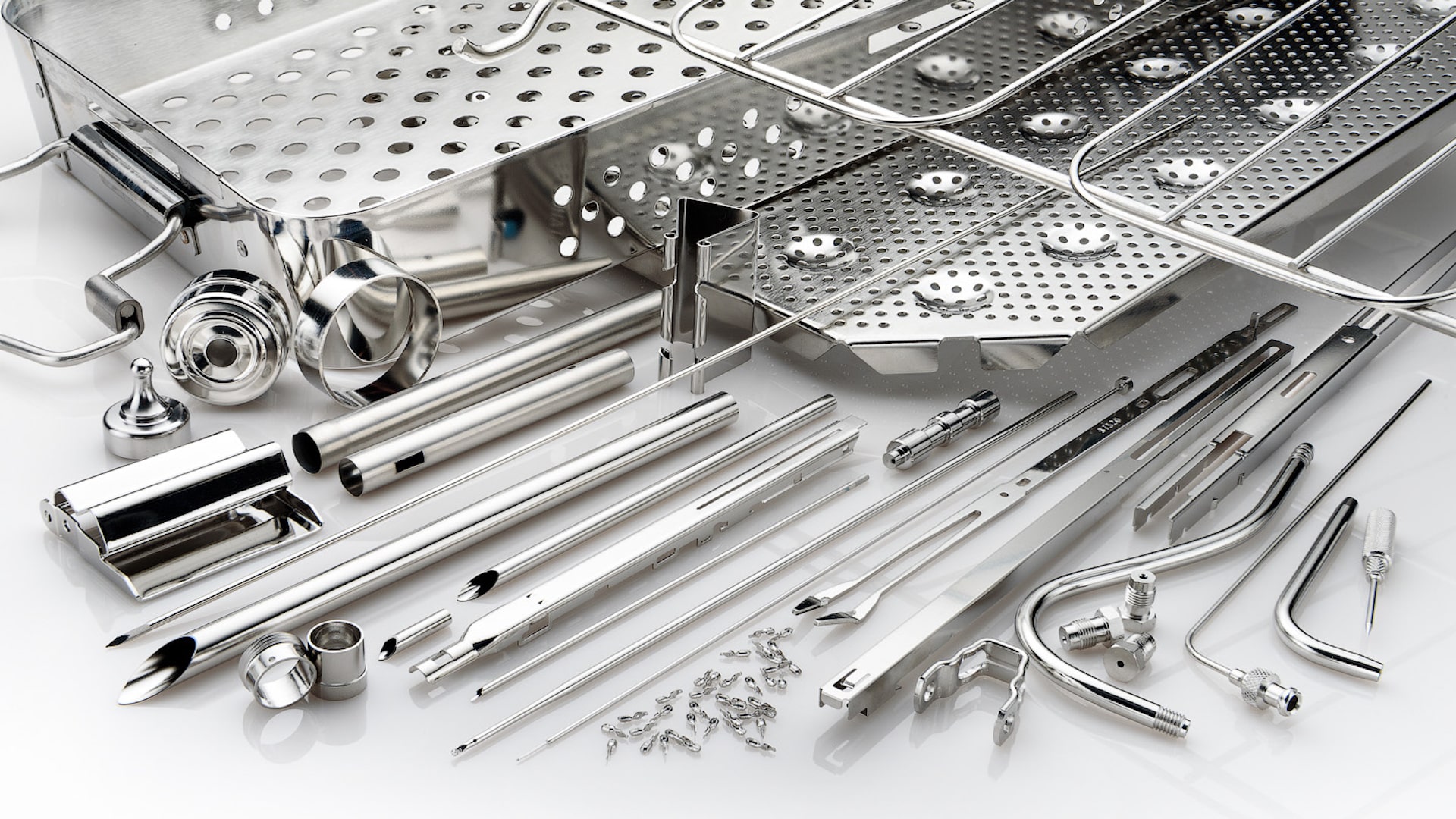

The medical industry demands precision, safety, and durability from its equipment and devices. From surgical tools to life-saving implants, these components must meet stringent standards to ensure patient safety and device efficacy. One critical finishing process that enables medical manufacturers to achieve these high standards is electropolishing medical devices.

Electropolishing, a chemical surface treatment process, removes microscopic surface imperfections, enhances corrosion resistance, and ensures a smooth, sterile finish. Here, we explore how electropolishing is applied to various medical devices and the advantages it brings to the table.

Surgical Instruments

Surgical tools such as scalpels, forceps, and retractors require a flawless surface for precise performance and ease of sterilization. Electropolishing:

- Improves Surface Smoothness: Removes burrs and micro-roughness, ensuring a non-porous surface that resists bacterial growth.

- Enhances Corrosion Resistance: Protects against pitting and degradation, especially during repeated sterilization cycles.

- Reduces Glare: Creates a uniform, matte finish that minimizes light reflection in operating rooms.

By electropolishing surgical tools, manufacturers ensure longevity, hygiene, and safety in critical healthcare settings.

Endoscopic and Minimally Invasive Tools

Endoscopic instruments and devices for minimally invasive surgeries must navigate delicate tissues with precision. Any imperfections can lead to tissue damage or reduced tool effectiveness. Electropolishing provides:

- Enhanced Smoothness: Ensures snag-free surfaces that minimize trauma to soft tissues.

- Optimal Cleanliness: Removes contaminants that could interfere with sterilization or patient safety.

- Durability: Increases the lifespan of intricate, high-use tools.

Electropolished tools contribute to the success of cutting-edge surgical techniques while maintaining patient safety.

Medical Implants

Devices such as stents, orthopedic implants, and dental implants require surfaces that integrate seamlessly with the human body. Electropolishing is instrumental in achieving this by:

- Boosting Biocompatibility: Produces a chemically inert surface that reduces the risk of adverse reactions.

- Improving Fatigue Resistance: Eliminates stress risers caused by surface irregularities, extending the implant’s lifespan.

- Enhancing Corrosion Resistance: Critical for implants exposed to bodily fluids, preventing degradation over time.

Whether it’s a hip replacement or a cardiovascular stent, electropolished implants provide superior performance and reliability.

Sterility and Hygiene Advantages

Across all applications, sterility is a non-negotiable factor in medical equipment. Electropolishing not only creates a visually appealing, bright finish but also optimizes cleanliness by removing contaminants and smoothing microscopic peaks and valleys that could harbor bacteria.

The Electropolishing Advantage in Medical Manufacturing

Medical device manufacturers face the dual challenge of meeting strict industry regulations while ensuring their products are safe and effective. By adopting electropolishing medical devices, companies can achieve:

- Consistent quality across product lines.

- Improved safety and performance of critical medical tools and implants.

- Compliance with FDA and ISO standards for medical-grade products.

Learn more about the electropolishing surface finish.

Conclusion

From surgical tools to implants, electropolishing plays a vital role in enhancing the safety, durability, and performance of medical devices. Its ability to produce smooth, sterile, and corrosion-resistant surfaces makes it a cornerstone of modern medical manufacturing.

To learn more about how electropolishing can benefit your medical device production, visit New England Electropolishing for expert solutions tailored to the medical industry.

Electropolishing Resources

What is Electropolishing?

Electropolishing is an electrochemical and reverse plating process that removes the outer layer of skin on a metal...

The Electropolishing Process

The electropolishing process is initiated by immersing a metal part into a temperature-controlled bath of electrolyte...

Benefits of Electropolishing

Curious about the benefits of putting your parts through the electropolishing process? Read along below where we...

How Much Material Does Electropolishing Remove?

Electropolishing, when done properly is a highly controllable process which removes as little as...

How Much Will Electropolishing Improve the Surface Finish of My Part?

Ra and RMS are both representations of surface roughness. Ra is calculated as the roughness average of a surface’s...

Electropolishing Frequently Asked Questions

Learn the difference between electropolishing and electroplating as well as how the electropolishing process works...

What is ASTM B912?

ASTM B912 is an industry standard for the passivation of stainless steel alloys through electropolishing...

What is ASTM A967?

ASTM A967 is an industry standard specification for the chemical passivation treatments for stainless...

What is ISO 13485?

ISO 13485 is a standard that applies specifically to medical devices. ISO 13485 is designed to be...