How Long Does Passivation Last? Factors That Affect Its Durability

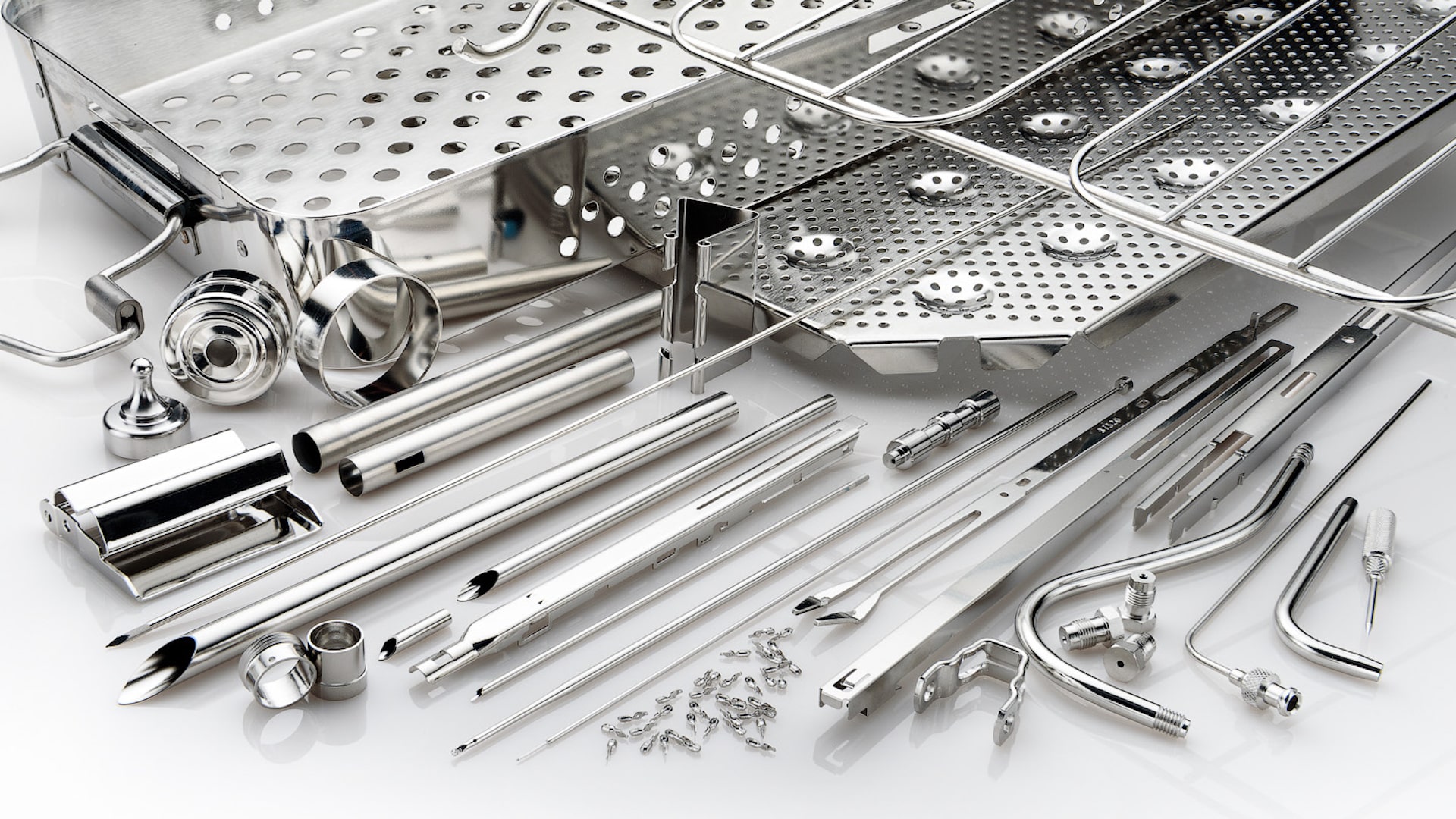

Stainless steel is known for its corrosion resistance, but without proper treatment, it can still be vulnerable to rust and contamination. Passivation of stainless steel is a crucial process that enhances its longevity by removing free iron from the surface and forming a protective oxide layer. However, one common question manufacturers ask is: How long does passivation last? The answer depends on several factors, including environmental conditions, material quality, and maintenance practices.

Understanding Stainless Steel Passivation

What is passivation? Stainless steel passivation is a chemical treatment that strengthens the metal’s natural resistance to corrosion. By removing contaminants and promoting the formation of a passive chromium oxide layer, this process ensures that stainless steel remains durable and resistant to oxidation in demanding applications.

Factors That Affect the Longevity of Passivation

1. Environmental Exposure

The conditions in which stainless steel operates play a significant role in determining how long passivation remains effective.

- Mild environments (indoor, low humidity, cleanroom applications) allow passivation to last for years without significant degradation.

- Aggressive environments (marine, high-humidity, or industrial settings with exposure to chlorides or harsh chemicals) can break down the passive layer faster, requiring more frequent passivation treatments.

2. Type of Stainless Steel

Different grades of stainless steel have varying levels of corrosion resistance. High-quality alloys, such as 316 stainless steel, offer superior resistance compared to 304 stainless steel, especially in chloride-rich environments. Choosing the right alloy for your application can extend the effectiveness of passivation.

3. Cleaning and Maintenance

Proper cleaning and maintenance are essential for preserving the passive layer. Using non-abrasive, stainless-steel-compatible cleaners prevents the introduction of contaminants that can compromise corrosion resistance. In industries like food processing and pharmaceuticals, routine cleaning with passivation-friendly agents can help maintain the integrity of the oxide layer.

4. Frequency of Repassivation

Over time, repeated exposure to harsh environments can wear down the passive layer, necessitating repassivation. The frequency depends on usage conditions, but industries dealing with high-corrosion risks, such as aerospace and medical device manufacturing, often implement regular passivation schedules to ensure continued protection.

5. Choice of Passivation Method

The type of passivation used affects its longevity. Citric acid passivation is an environmentally friendly alternative to nitric acid passivation, offering effective corrosion resistance without introducing toxic byproducts. Choosing the right passivation method ensures longer-lasting protection for stainless steel components.

When Should Stainless Steel Be Repassivated?

The need for repassivation varies based on application and environment. Signs that stainless steel may require repassivation include:

- Visible discoloration or rust spots

- Decreased corrosion resistance in performance testing

- Regular exposure to harsh chemicals or saltwater environments

Many manufacturers incorporate routine passivation as part of their maintenance schedule to ensure continued performance.

Partner with a Passivation Expert

At New England Electropolishing, we specialize in providing high-quality passivation solutions tailored to critical industries, including medical, aerospace, and food processing. Whether you need passivation of stainless steel with citric acid or a customized finishing process, our expertise ensures your components remain corrosion-resistant and meet industry standards.

Conclusion

The longevity of passivation depends on multiple factors, including environmental exposure, material quality, and maintenance practices. While passivation can last for years in controlled conditions, industries operating in harsh environments may require periodic repassivation to maintain stainless steel’s integrity. By choosing the right passivation method and working with an experienced provider like New England Electropolishing, manufacturers can maximize the lifespan and performance of their stainless steel components.

For more information on passivation solutions, contact New England Electropolishing today.

Electropolishing Resources

What is Electropolishing?

Electropolishing is an electrochemical and reverse plating process that removes the outer layer of skin on a metal...

The Electropolishing Process

The electropolishing process is initiated by immersing a metal part into a temperature-controlled bath of electrolyte...

Benefits of Electropolishing

Curious about the benefits of putting your parts through the electropolishing process? Read along below where we...

How Much Material Does Electropolishing Remove?

Electropolishing, when done properly is a highly controllable process which removes as little as...

How Much Will Electropolishing Improve the Surface Finish of My Part?

Ra and RMS are both representations of surface roughness. Ra is calculated as the roughness average of a surface’s...

Electropolishing Frequently Asked Questions

Learn the difference between electropolishing and electroplating as well as how the electropolishing process works...

What is ASTM B912?

ASTM B912 is an industry standard for the passivation of stainless steel alloys through electropolishing...

What is ASTM A967?

ASTM A967 is an industry standard specification for the chemical passivation treatments for stainless...

What is ISO 13485?

ISO 13485 is a standard that applies specifically to medical devices. ISO 13485 is designed to be...