Our Quality Process

Strict Attention to detail that exceeds your expectations.

NEE processes thousands of orders annually from hundreds of customers throughout the United States. At the center of our operation is an intricate computer system that helps us manage estimating, scheduling, processing, accounting, shipping and invoicing. This system ensures consistency in quality, so your order is processed right the first time.

Every part that NEE electropolishes receives specific computerized procedures detailing all operating parameters to include:

- Incoming Inspection Criteria

- Acid Pickling

- Alkaline Soak

- Custom Cathode Requirement

- Amperage

- Voltage

- Time

- Temperature

- Cathode Configuration

- Solution

- Agitation

- In-process Inspection Criteria

- Removal Rate

- Packaging

- Final Inspection Criteria

Every job progresses through our plant with a detailed “work ticket” and all trained operators and inspectors are required to initial and verify that they performed each of the necessary operations. NEE provides complete job traceability by lot and order number and, for your convenience, maintains these records for a minimum of seven years.

This strict attention to detail allows NEE to meet or exceed your specific requirements.

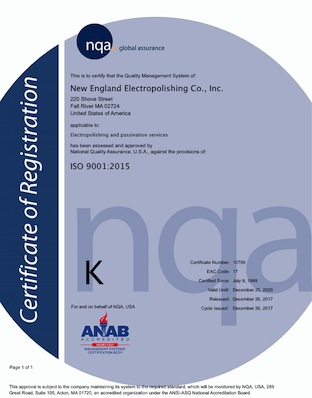

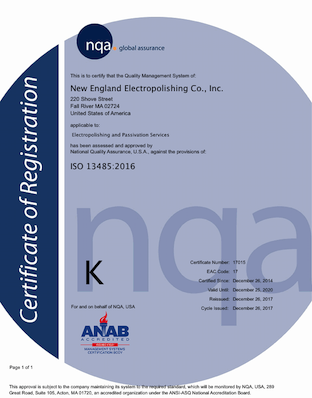

Certifications

Validations

New England Electropolishing has a validated electropolishing line (full IQ, OQ PQ) dedicated to the processing of medical instruments and components.

NEE processes groups of components on other lines which are periodically tested by an independent laboratory for meeting the requirements of ASTM B912, “Standard Specification for Passivation of Stainless Steel Using Electropolishing,” and ASTM A967, “Standard Specification for Chemical Passivation Treatments for Stainless Steel Parts.”

As an additional service to customers, NEE can verify process output by performing in-house Copper Sulfate Testing.

Process risk is evaluated via the use of Process Failure Mode Effects Analysis (PFMEA) methodology.

NEE welcomes the opportunity to work with Medical Device customers to provide tailored validation/verification activities in response to specific project requirements. Depending on the scope of the validation/verification activity, additional fees may apply. Please contact us to discuss.