What is Electropolishing?

Electropolishing is an electrochemical or “reverse plating” process that removes the outer layer of “skin” on a metal part to address microscopic imperfections within its finish —as opposed to electroplating, which deposits metal onto the finished surface. Electropolishing is commonly used to clean, deburr and passivate parts as part of the manufacturing process.

How Electropolishing Works

Electropolishing will smooth and streamline the microscopic surface of most metal objects, improve surface finish, improve corrosion resistance and achieve passivation—typically stainless steel or similar alloys. Electropolishing typically takes off between 0.0002 and 0.0003 of an inch from the surface of an object. Learn more about how much material electropolishing removes.

The electropolishing process may improve the surface finish of your metal part by 10%-40% (depending on part tolerances and surface finish) or more—rendering the surface of the metal microscopically featureless and void of any tiny imperfections. Often, during a standard run, total material removal is limited between 0.0002” to 0.0003” per surface—but the removal rate can be adjusted depending on a part’s tolerances.

It’s important to note that electropolishing only improves the surface of a metal part on a microscopic level. Any macroscopic textures or surface scratches will only result in a smoother texture or smoothed scratch if taken through the electropolishing process. For macroscopic surface imperfections, mass finishing is the more appropriate process for the job.

The Electropolishing Process

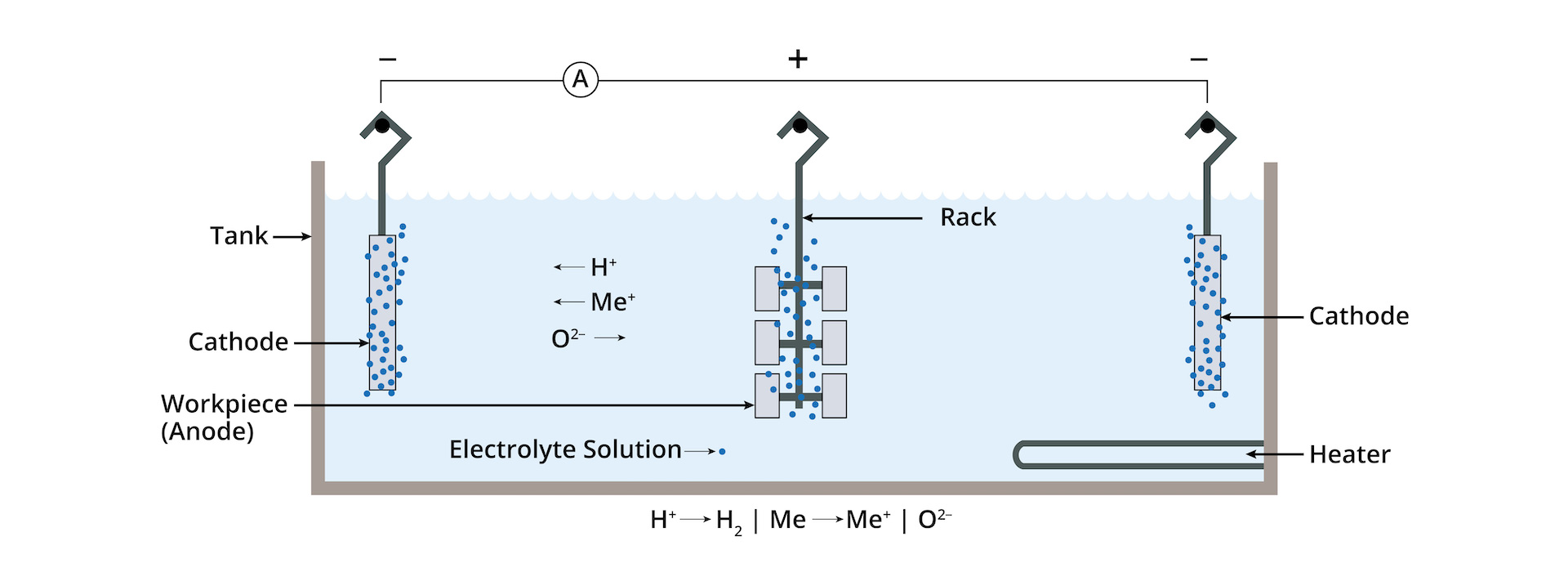

How do we do it? We first load the parts onto racks, which we dip into a tank filled with a phosphoric and sulfuric acid solution. The tank is lined with metal plates that function as cathodes so we can run a positive electric current through the bath.

We can adjust the removal rate to a specified tolerance, and we check throughout our process to ensure we are meeting the targets we set. This is especially important during electropolishing of large batches of parts, so we ensure that our quality is consistent from the first part to the last. Learn more about the electropolishing process.

How the Electropolishing Process Works at NEE

1. Surface Preparation

Before electropolishing begins, each part goes through a meticulous cleaning stage to remove any oils, machining residues, or heat-affected discoloration from prior manufacturing processes. This ensures that the metal surface is completely clean and ready to be evenly polished.

2. Part Fixturing

Parts are mounted based on their size, geometry, and tolerance requirements. Smaller components may be processed in custom-designed baskets for batch treatment, while precision parts—such as those used in medical or aerospace applications—are individually fixtured to achieve optimal, uniform results.

3. The Electropolishing Bath

Once racked, components are introduced into an electrolyte solution, typically made from a carefully calibrated mix of sulfuric and phosphoric acids. A controlled electrical current is applied, dissolving surface material at a microscopic level. The process targets peaks more than valleys, smoothing the surface while simultaneously removing embedded contaminants.

4. Rinse and Neutralization Sequence

Following electropolishing, parts enter a multistage rinsing and neutralization process. These steps may involve several different acid baths, clean water rinses, and up to ten stages of deionized water to eliminate all chemical residues. Drying methods are tailored to part geometry and sensitivity to ensure cleanliness and integrity.

5. Inspection and Testing

To confirm process effectiveness and meet customer standards, parts are inspected and, if needed, tested. For example, copper sulfate testing can be performed to verify passivation. High-precision parts may also be measured at different stages to ensure critical dimensions remain intact.

6. Packaging and Delivery

Before shipment, all components go through a final inspection by NEE’s quality team. Special attention is paid to handling and packaging, especially for delicate or high-spec components. Custom trays and packaging materials are used to prevent metal-on-metal contact and to ensure parts arrive in pristine condition.

Can Electropolishing Achieve Passivation? Yes.

The Passivation of stainless steel is the removal of free iron from the surface of a part. Electropolishing will remove free iron, as well as de-burr and deeply clean the surface. This can be especially important when you have small parts with trace amounts of free iron and micro-burrs.

The passivation of stainless steel at NEE can be performed to industry standards such as ASTM A967 and ASTM B912.

To learn more about Electropolising, please watch the video on this page or visit our electropolishing resources page for more information.

Understanding Electrochemical Polishing

Electrochemical polishing serves as an umbrella term encompassing various specialized processes aimed at refining metal surfaces through controlled chemical reactions. These processes include electropolishing, citric acid passivation, electrolytic polishing, and more. Each method offers unique advantages and applications, but they all share the common goal of achieving superior surface quality and finish. Whether it’s enhancing corrosion resistance, improving aesthetic appeal, or optimizing functionality, electrochemical polishing techniques provide versatile solutions for a wide range of industries, from aerospace and automotive to medical devices and beyond. Contact us today to discuss what would be the ideal treatment for your needs.

Electrolytic Polishing

In the world of metal finishing, the terms “electropolishing” and “electrolytic polishing” often coexist, but they aren’t interchangeable. Electrolytic Polishing sometimes referred to as Electrolytic CMP or E-CMP is a metal finishing process that combines elements of CMP (chemical mechanical polishing) with that of electro-dissolution. While both processes involve the use of electric current to polish metal surfaces, the gold standard for stainless steel passivation remains Electropolishing. This specialized technique offers a level of precision and quality that surpasses traditional methods, ensuring metal components achieve a flawlessly smooth, corrosion-resistant finish.

At New England Electropolishing, we stand by the importance of accurate terminology and feel it’s important for our customers to understand the difference between electrolytic polishing and electropolishing. Electropolishing is not just a process; it’s a refined science, meticulously designed to enhance the surface of metal alloys to perfection. Our expert team of electropolishers understands the nuances of this technique, ensuring your components are treated with the utmost care, resulting in an unparalleled level of quality and durability.

Frequently Asked Questions

Does electropolishing remove material from the surface?

Yes, electropolishing removes a very thin, controlled layer of material — typically between 0.0001″ and 0.001″ (2.5 to 25 microns) — depending on alloy type, surface condition, and process time.

This removal is what levels micro-peaks, smooths the surface, and enhances the chromium-to-iron ratio, resulting in a more corrosion-resistant and reflective finish.

How does electropolishing improve corrosion resistance?

This passive film forms naturally and provides superior protection against rust, pitting, and environmental attack — a benefit especially critical in medical, semiconductor, and food processing applications.

Is electropolishing the same as passivation?

No — while both improve corrosion resistance, they work differently.

-

Passivation is a chemical cleaning process that removes free iron without altering the surface texture or geometry.

-

Electropolishing, on the other hand, is an electrochemical finishing process that actually removes a microscopic layer of metal, smoothing and brightening the surface.

For more detail, see our full comparison: Electropolishing vs. Passivation.

Can electropolishing change part dimensions or tolerances?

However, for precision components with tight dimensional requirements, our process engineers can calculate expected removal rates and adjust processing times to maintain critical dimensions.

What surface finishes can electropolishing achieve?

Depending on the starting condition, improvements of 30–50% in surface smoothness are common — transforming machined, ground, or welded parts into mirror-bright, micro-smooth surfaces that resist corrosion and are easier to clean.

Is electropolishing environmentally friendly?

Compared to mechanical finishing, electropolishing is a cleaner, closed-loop process.

NEE uses advanced waste treatment and electrolyte recovery systems to minimize environmental impact and maintain compliance with all EPA and state regulations.

We also offer citric acid passivation as a safer, biodegradable alternative to nitric-based chemistries. Learn more about it here.

Is electropolishing environmentally friendly?

Compared to mechanical finishing, electropolishing is a cleaner, closed-loop process.

NEE uses advanced waste treatment and electrolyte recovery systems to minimize environmental impact and maintain compliance with all EPA and state regulations.

We also offer citric acid passivation as a safer, biodegradable alternative to nitric-based chemistries. Learn more about it here.

What types of stainless steel can be electropolished?

Nearly all common grades of stainless steel respond well to electropolishing, including:

-

Austenitic: 304, 316, 316L, 321

-

Martensitic: 410, 420, 440

-

Precipitation-hardened: 17-4PH, 15-5PH

Our team also works with specialty alloys and can advise on optimal parameters for each material type.

What industries rely on electropolishing?

Electropolishing is widely used anywhere cleanliness, precision, and corrosion resistance are critical, including:

-

Medical device manufacturing

-

Aerospace and defense

-

Semiconductor fabrication

-

Food and beverage processing

-

Pharmaceutical and biotech equipment

-

Energy and fluid handling systems

How do you verify surface finish and corrosion performance?

At NEE, every electropolished part undergoes inspection and testing to verify quality.

We use profilometers to measure surface roughness (Ra/RMS), visual and microscopic inspection for defects, and corrosion testing as required by ASTM and AMS standards.

Data is recorded for traceability and provided with certification upon request.

Can electropolishing be combined with passivation?

How can I determine if electropolishing is right for my parts?

The best approach depends on your material, surface condition, and application.

If you need smoother finishes, reduced contamination risk, and enhanced corrosion performance, electropolishing is usually ideal.

Our team can help evaluate your needs — contact us today to discuss your project or request sample processing.

Electropolishing before and after examples

High Treated Machined Parts

Our small part electropolishing process will remove heat scale and contaminates on a parts’ surface while keeping material removal to a minimum (.0001-.0002” precision).

Level Floats

Electropolishing removes weld discoloration while producing a mirror finish that is corrosion resistant.

Surgical Clips

Oxide is removed through Electropolishing creating a mirror finish.

Small Electropolished Rings & Tubes

OD and ID finishing of High Purity Ring-Internal Ra 8.

Case Study Spotlight: Real-World Results of Electropolishing

See how precision electropolishing transformed stainless steel components for a prominent Boston waterfront project. By improving surface finish and corrosion resistance, the treated parts achieved dramatically extended service life in harsh maritime conditions. Read the full case study here: Electropolishing Case Study – Battery Wharf, Boston, MA.

Electropolishing Resources

What is Electropolishing?

Electropolishing is an electrochemical and reverse plating process that removes the outer layer of skin on a metal...

The Electropolishing Process

The electropolishing process is initiated by immersing a metal part into a temperature-controlled bath of electrolyte...

Benefits of Electropolishing

Curious about the benefits of putting your parts through the electropolishing process? Read along below where we...

How Much Material Does Electropolishing Remove?

Electropolishing, when done properly is a highly controllable process which removes as little as...

How Much Will Electropolishing Improve the Surface Finish of My Part?

Ra and RMS are both representations of surface roughness. Ra is calculated as the roughness average of a surface’s...

Electropolishing Frequently Asked Questions

Learn the difference between electropolishing and electroplating as well as how the electropolishing process works...

What is ASTM B912?

ASTM B912 is an industry standard for the passivation of stainless steel alloys through electropolishing...

What is ASTM A967?

ASTM A967 is an industry standard specification for the chemical passivation treatments for stainless...

What is ISO 13485?

ISO 13485 is a standard that applies specifically to medical devices. ISO 13485 is designed to be...