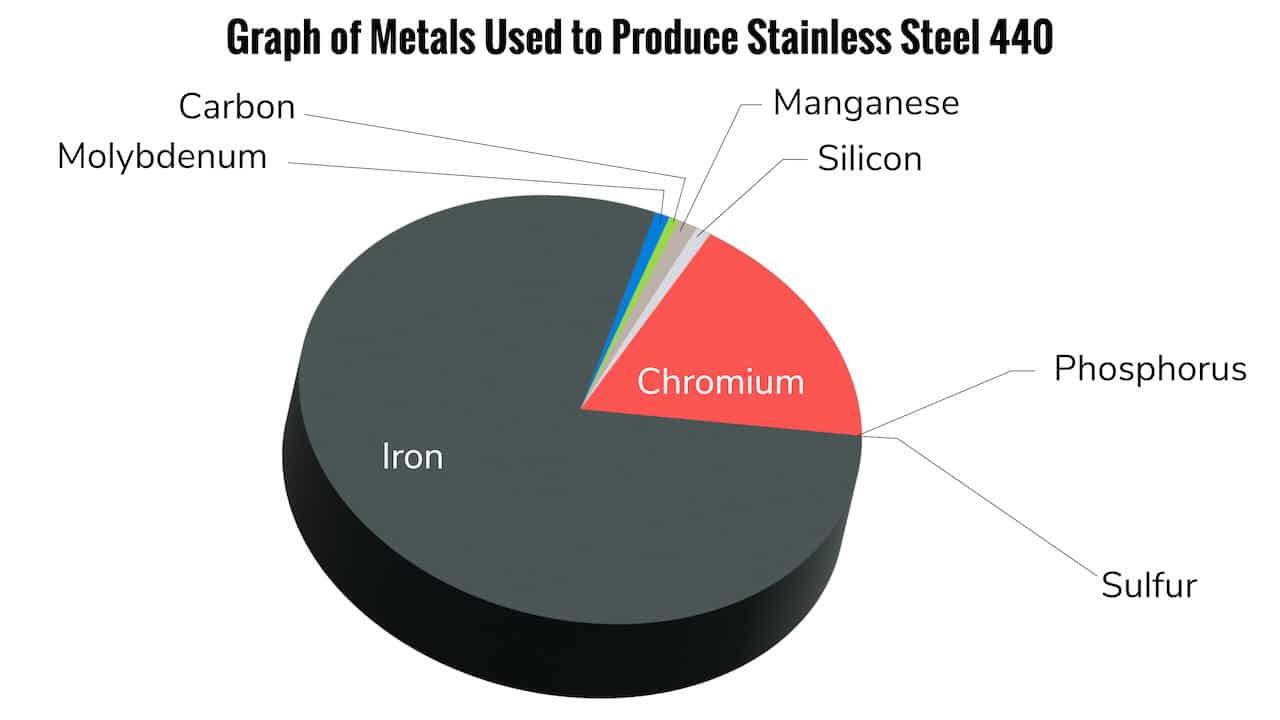

Understanding Grade 440 Stainless Steel

Grade 440 stainless steel comes in multiple variations (440A, 440B, and 440C), each offering a different balance of hardness and corrosion resistance. Known for its extremely high hardness and superior edge retention, 440 stainless steel is commonly used in high-quality cutlery, ball bearings, and valve components.

History of 440 Stainless Steel

440 stainless steel was developed to meet the demand for an alloy that could deliver an exceptional combination of hardness, corrosion resistance, and edge retention. The material’s emergence was crucial in industries like cutlery, where sharpness and durability are paramount, as well as in precision machinery.

Advantages of 440 Stainless Steel

- Extremely High Hardness: Grade 440C, in particular, is one of the hardest stainless steels available, making it suitable for cutting tools, surgical instruments, and high-wear parts.

- Excellent Edge Retention: 440 stainless steel is prized for its ability to maintain a sharp edge over long periods, making it ideal for premium knives and cutting tools.

- Good Corrosion Resistance: While not as corrosion-resistant as austenitic stainless steels, 440 stainless steel provides excellent resistance in many applications, especially when properly heat-treated.

Disadvantages of 440 Stainless Steel

- Difficult to Machine: Due to its hardness, 440 stainless steel can be more challenging to machine and work with compared to softer grades like 304 or 316.

- Brittleness in High-Strength Applications: The high hardness of 440C can also result in brittleness, making it less suitable for applications where impact resistance or flexibility is crucial.

Common Applications of 440 Stainless Steel

Grade 440, especially the 440C variant, is highly prized for its hardness, making it useful in a wide range of high-stress and high-wear applications:

- High-End Cutlery: 440C is frequently used in premium knives, both kitchen and outdoor, where long-lasting sharpness is essential.

- Ball Bearings: The wear resistance and hardness of 440 stainless steel make it a preferred material for ball bearings in machinery.

- Valve Components and Pumps: Often used in environments requiring parts with high wear resistance and moderate corrosion resistance.

- Surgical and Dental Tools: Like 420, 440 is used for surgical instruments that require excellent cutting edges and durability.

- Industrial Blades and Tools: Ideal for industrial cutting tools, razor blades, and other instruments where sharpness and hardness are critical.