Understanding 317 Grade Stainless Steel

What is 317 Grade Stainless Steel?

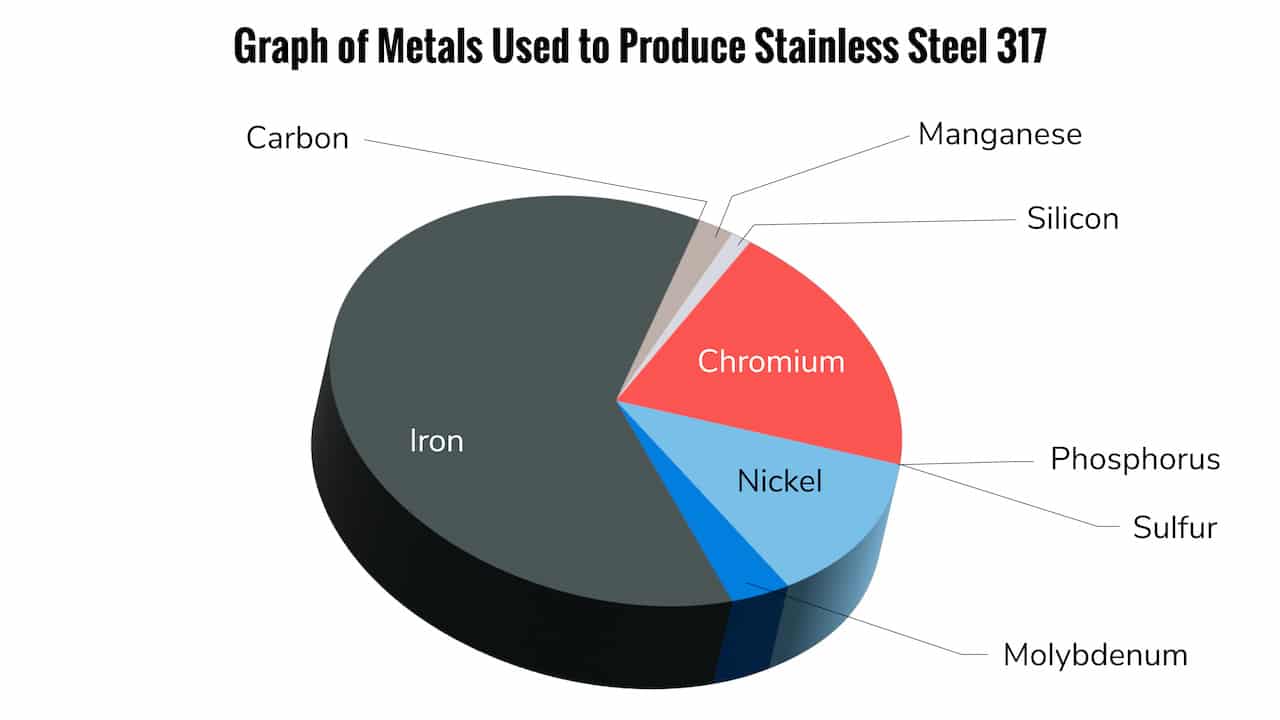

317 stainless steel is part of the austenitic family, containing approximately 18-20% chromium, 11-15% nickel, and 3-4% molybdenum. This high molybdenum content is what distinguishes 317 from grades like 316 and gives it enhanced resistance to corrosion, particularly in environments where strong acids or chlorides are present.

There are also low-carbon variants, such as 317L, which offer better weldability and reduced risk of corrosion in the heat-affected zones of welds.

History of 317 Stainless Steel

The development of stainless steel began in the early 20th century when metallurgists started adding chromium to steel to create a rust-resistant material. Over time, the need for stainless steel that could withstand even more aggressive chemicals led to the introduction of high-molybdenum grades like 316 and 317. The latter was developed to perform exceptionally well in environments where standard stainless steels would corrode too quickly, such as chemical processing plants and marine environments.

Advantages of 317 Grade Stainless Steel

-

Superior Corrosion Resistance: One of the standout features of 317 stainless steel is its enhanced corrosion resistance, particularly in environments that contain high concentrations of acids, chlorides, and other corrosive substances. The higher molybdenum content provides exceptional resistance to pitting and crevice corrosion.

-

High-Temperature Strength: 317 grade maintains its strength and corrosion resistance at elevated temperatures, making it a preferred material for equipment exposed to heat and chemical reactions.

-

Good Weldability and Formability: Like other austenitic stainless steels, 317 can be easily welded, formed, and fabricated. The low-carbon variant (317L) helps prevent issues like intergranular corrosion in the heat-affected zones of welded components.

-

Durability and Longevity: Due to its robust composition, 317 grade stainless steel is highly durable and can withstand harsh environmental conditions for extended periods, reducing the need for frequent replacements or repairs.

Disadvantages of 317 Grade Stainless Steel

-

Cost: The primary drawback of 317 stainless steel is its cost. The increased molybdenum and nickel content makes it more expensive than grades like 304 or even 316. This higher cost may not be justified in applications where the additional corrosion resistance isn’t necessary.

-

Limited Availability: Because 317 grade is not as commonly used as 304 or 316, it may not be as readily available. Special ordering may be required for some projects, leading to longer lead times.

-

Weight: 317 stainless steel is slightly denser and heavier than lower alloyed grades, which could be a consideration for applications where weight is a critical factor.

Common Applications of 317 Grade Stainless Steel

Due to its superior resistance to corrosion, 317 grade stainless steel is often used in industrial environments where exposure to aggressive chemicals, high temperatures, or salty conditions are common. Typical applications include:

-

Chemical Processing: 317 stainless steel is often used in the production of chemical reactors, heat exchangers, evaporators, and piping systems exposed to acids, solvents, and other corrosive chemicals.

-

Pharmaceutical and Food Processing Equipment: The high corrosion resistance of 317 stainless steel makes it ideal for pharmaceutical manufacturing and food processing equipment that must withstand acidic substances and maintain hygiene standards.

-

Marine Environments: The enhanced chloride resistance makes 317 suitable for marine applications like shipbuilding, offshore oil rigs, and coastal architectural structures.

-

Pulp and Paper Industry: The pulp and paper industry often requires materials that can resist the acidic chemicals used in production, making 317 a good fit for storage tanks, pipes, and other equipment.

-

Petrochemical and Refining: In environments where oil, gas, and chemical processing equipment are exposed to corrosive substances, 317 stainless steel provides the durability needed for long-term operation.

Conclusion

317 grade stainless steel offers exceptional corrosion resistance, particularly in chemical-rich environments, due to its higher levels of molybdenum and nickel. While its cost and availability can be limiting factors, it’s a highly valuable material for industries where durability, high-temperature resistance, and protection against aggressive chemicals are essential.

With applications spanning chemical processing, marine environments, and food and pharmaceutical manufacturing, 317 stainless steel remains a critical material for projects requiring long-lasting performance in challenging conditions.